Brings you the Best Solution for

Industrial Pump

KZ Series Wide-channel Pulp Pump

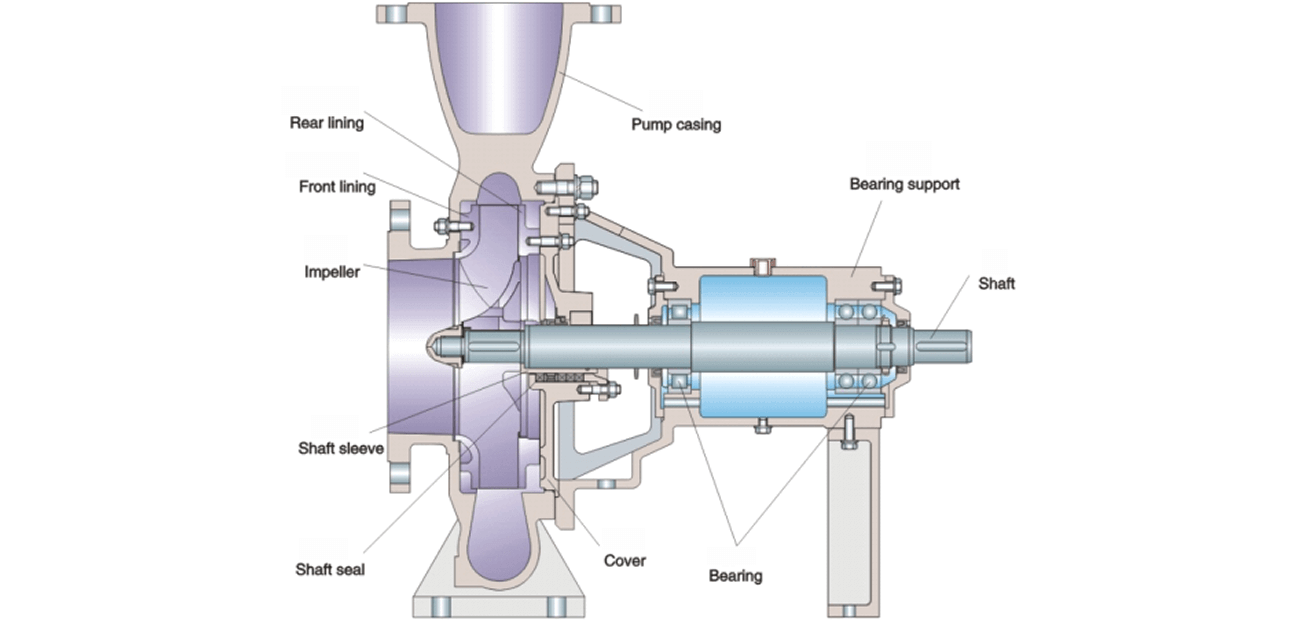

- Design: Single stage and single suction centrifugal pump.

- Medium: Pulp and pulp containing air of consistency up to 6% / Similar liquids

- Material of Construction (Wetted parts) : Cast iron/Stainless steel/Wear resistant duplex stainless steel.

- Shaft seal: Stuffing box seal/Mechanical seal.

- Impeller: Open impeller with 3 or 6 blades

- Application: Pulp and paper industry, Environment protection industry.

KZ Series Wide-channel Pulp Pump

KZ Series Wide-channel Pulp Pump

Characteristics

- Assembly facilitates easy dismounting for maintenance. Using the standard diaphragm coupling with intermediate shaft, the impeller, rear lining, shaft seal part and bearing support can be dismounted and mounted as a push and pull part without removing the inlet and outlet pipes of the pump.

- All the spare parts are common and standardized. Reduce the inventory of spare parts greatly.

- High efficiency, energy saving and stable operation. By using the latest Computational Fluid Dynamics (CFD) technique to optimize the hydraulic performance of impeller and pump casing, the open impeller can reduce the pressure at the shaft seal and minimize the leakage.

- The gap of front and rear wear lining is adjustable to improve the performance.

- Major wetted parts are made by wax-lost precision casting to ensure the smooth inner wall. The impeller is checked by G6.3 dynamic balancing test.

| Outlet Diameter | DN40 to DN500 |

| Flow Rate | ≤3400m3/h |

| Head | ≤80m |

| Pressure Grade | 1.0MPa |

| Temperature | ≤120°C |

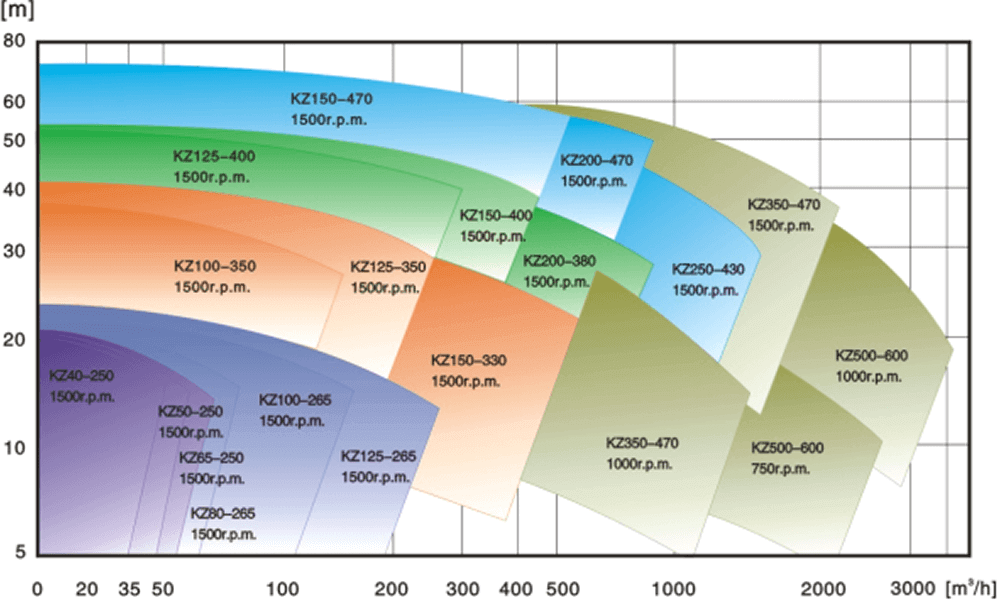

Performance Curve of KZ, n=1500rpm(1000rpm, 750rpm)

Pump Selection Chart

| Pump Model | Imp.Dia (mm) | Flow (m3/h) | Head (m) | Speed (r/min) | Shaft P(kw) | P(Kw) | [NPSH]r (m) | Pump Wt.(Kg) | Inlet Dia. (mm) | Outlet Dia. (mm) | Bearing Support |

|---|---|---|---|---|---|---|---|---|---|---|---|

| KZ40-250 | ∅250 | 20 | 15 | 1500 | 2.2 | 3 | 2.5 | 165 | 65 | 40 | KZ24 |

| ∅230 | 18 | 12.5 | 1.5 | 2.2 | |||||||

| ∅210 | 16 | 10 | 1.1 | 2.2 | |||||||

| ∅190 | 15 | 7.5 | 0.9 | 1.5 | |||||||

| KZ50-250 | ∅250 | 35 | 17.5 | 1500 | 3.1 | 4 | 2.5 | 176 | 80 | 50 | |

| ∅230 | 32 | 14.5 | 2.1 | 3 | |||||||

| ∅210 | 29 | 12 | 1.6 | 2.2 | |||||||

| ∅190 | 26 | 10 | 1.2 | 2.2 | |||||||

| KZ65-250 | ∅250 | 50 | 16.5 | 1500 | 4.0 | 5.5 | 2.5 | 186 | 100 | 65 | |

| ∅230 | 46 | 14 | 3.0 | 4.0 | |||||||

| ∅210 | 42 | 11.5 | 2.1 | 3.0 | |||||||

| ∅190 | 38 | 9.5 | 1.4 | 2.2 | |||||||

| KZ80-265 | ∅265 | 70 | 15 | 1500 | 4.5 | 5.5 | 2.5 | 196 | 100 | 80 | KZ28 |

| ∅245 | 60 | 13 | 3.3 | 4 | |||||||

| ∅225 | 50 | 11 | 2.3 | 3 | |||||||

| ∅205 | 40 | 9 | 1.6 | 2.2 | |||||||

| KZ100-265 | ∅265 | 100 | 17 | 1500 | 6.8 | 11 | 2.5 | 207 | 125 | 100 | |

| ∅245 | 90 | 14 | 5 | 7.5 | |||||||

| ∅225 | 80 | 11 | 3.5 | 4 | |||||||

| ∅205 | 70 | 8.5 | 2.6 | 3 | |||||||

| KZ125-265 | ∅265 | 175 | 16 | 1500 | 10.2 | 15 | 4.0 | 218 | 150 | 125 | |

| ∅245 | 150 | 13 | 7.2 | 11 | |||||||

| ∅225 | 125 | 10 | 5.1 | 5.5 | |||||||

| ∅205 | 100 | 7 | 3.1 | 4 | |||||||

| KZ100-350 | ∅350 | 120 | 28 | 1500 | 13.8 | 15 | 2.5 | 298 | 125 | 100 | KZ38A |

| ∅330 | 110 | 25 | 11.3 | 15 | |||||||

| ∅310 | 100 | 23 | 8.8 | 11 | |||||||

| ∅290 | 90 | 18 | 7.1 | 11 | |||||||

| KZ125-350 | ∅350 | 200 | 32 | 1500 | 24 | 30 | 4.0 | 310 | 150 | 125 | |

| ∅330 | 175 | 28 | 19 | 22 | |||||||

| ∅310 | 150 | 25 | 15 | 18.5 | |||||||

| ∅290 | 125 | 21.5 | 11.3 | 15 | |||||||

| KZ150-330 | ∅330 | 350 | 26 | 1500 | 32.2 | 37 | 4.5 | 317 | 200 | 150 | KZ38B |

| ∅310 | 300 | 22 | 24 | 30 | |||||||

| ∅290 | 250 | 18 | 17.5 | 22 | |||||||

| ∅270 | 200 | 14.5 | 12.8 | 15 | |||||||

| KZ125-400 | ∅400 | 225 | 40 | 1500 | 33.8 | 45 | 3.5 | 406 | 150 | 125 | KZ42A |

| ∅380 | 200 | 36.5 | 27 | 37 | |||||||

| ∅360 | 175 | 33 | 21.2 | 30 | |||||||

| ∅340 | 150 | 30 | 17 | 22 | |||||||

| KZ150-400 | ∅400 | 300 | 44 | 1500 | 50 | 75 | 2.5 | 460 | 200 | 150 | |

| ∅380 | 275 | 38.5 | 40.1 | 55 | |||||||

| ∅360 | 250 | 34 | 32 | 37 | |||||||

| ∅340 | 225 | 30 | 26 | 30 | |||||||

| KZ00-380 | ∅380 | 550 | 35 | 1500 | 66 | 75 | 3.0 | 487 | 250 | 200 | KZ42B |

| ∅360 | 500 | 30.5 | 54 | 75 | |||||||

| ∅340 | 450 | 27 | 44 | 55 | |||||||

| ∅320 | 400 | 24 | 37 | 45 | |||||||

| KZ150-470 | ∅470 | 500 | 55 | 1500 | 97.6 | 110 | 4.5 | 696 | 200 | 150 | KZ55A |

| ∅430 | 450 | 44 | 70 | 90 | |||||||

| ∅390 | 400 | 33 | 47.8 | 55 | |||||||

| ∅350 | 350 | 25 | 31.3 | 37 | |||||||

| KZ200-470 | ∅470 | 600 | 57 | 1500 | 122 | 160 | 3.5 | 718 | 250 | 200 | |

| ∅430 | 550 | 45 | 88 | 110 | |||||||

| ∅390 | 500 | 35 | 62 | 75 | |||||||

| ∅350 | 450 | 25 | 42 | 45 | |||||||

| KZ50-430 | ∅430 | 1000 | 43 | 1500 | 145 | 160 | 4.5 | 812 | 300 | 250 | KZ55B |

| ∅390 | 900 | 32 | 100 | 110 | |||||||

| ∅350 | 800 | 23 | 68 | 75 | |||||||

| ∅320 | 700 | 18 | 50 | 55 | |||||||

| KZ350-470 | ∅470 | 1500 | 45 | 1500 | 225 | 250 | 6.5 | 1660 | 350 | 350 | KZ80 |

| ∅430 | 1400 | 36 | 166 | 200 | |||||||

| ∅390 | 1300 | 27 | 125 | 160 | |||||||

| ∅350 | 1200 | 22 | 96 | 132 | |||||||

| KZ350-470 | ∅470 | 1000 | 20 | 1000 | 65 | 75 | 3.5 | 1660 | |||

| ∅430 | 950 | 15 | 48 | 55 | |||||||

| ∅390 | 900 | 11.5 | 36.3 | 45 | |||||||

| ∅350 | 850 | 9 | 28 | 37 | |||||||

| KZ500-600 | ∅600 | 2500 | 30 | 1000 | 238.3 | 280 | 4.5 | 2380 | 500 | 500 | |

| ∅550 | 2200 | 24 | 174 | 200 | |||||||

| ∅500 | 2000 | 18 | 129.3 | 160 | |||||||

| ∅450 | 1800 | 15 | 103.4 | 132 | |||||||

| KZ500-600 | ∅600 | 1800 | 17 | 750 | 99.2 | 132 | 3.0 | 2380 | |||

| ∅550 | 1650 | 13 | 72.8 | 90 | |||||||

| ∅500 | 1500 | 10 | 54.3 | 75 | |||||||

| ∅450 | 1400 | 8 | 43.2 | 55 |