Brings you the Best Solution for

industrial Pumps

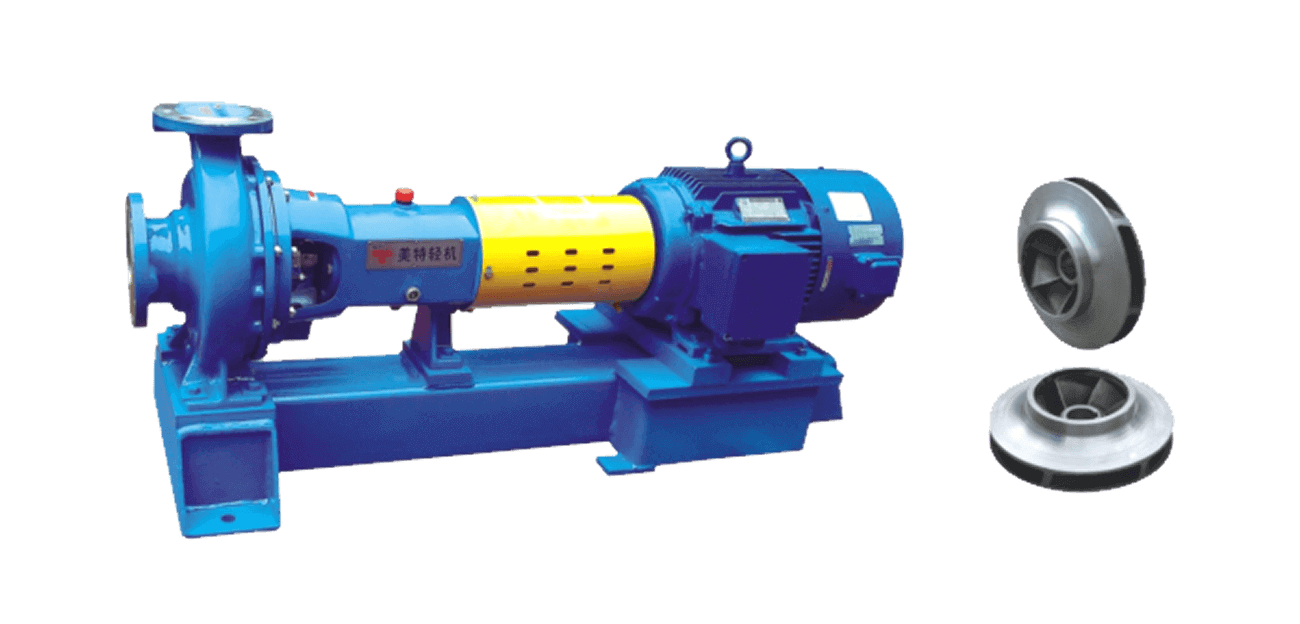

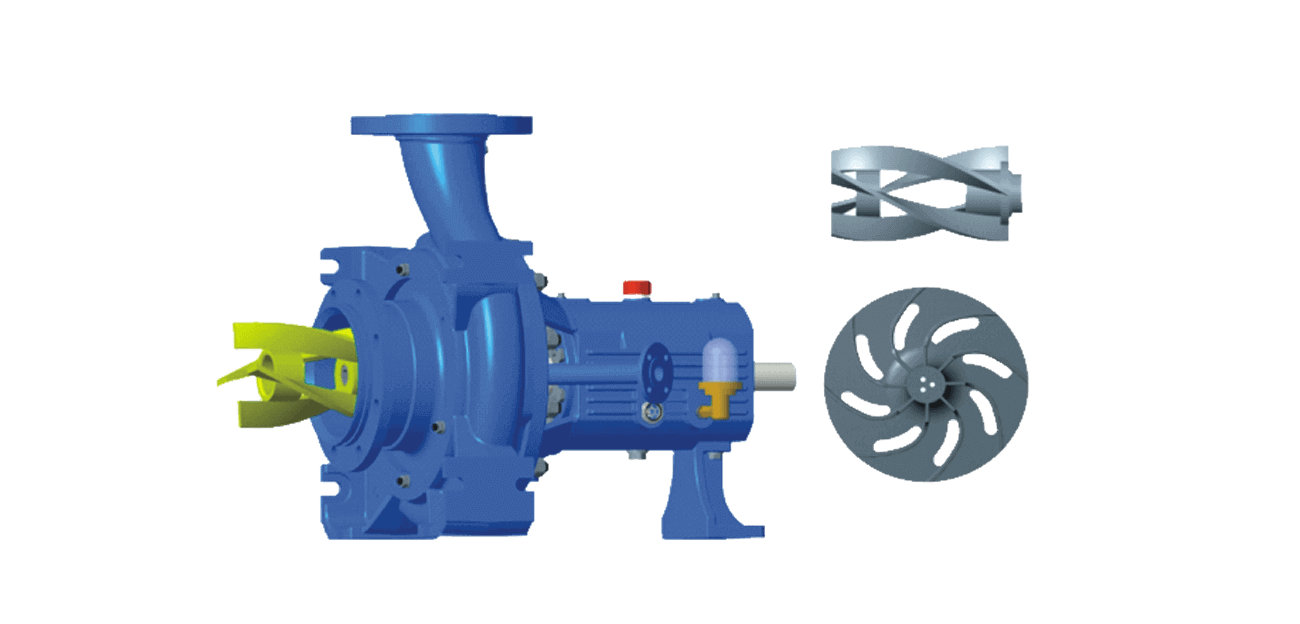

KZ Series Wide-channel Pulp Pump

- Design: Single stage and single suction centrifugal pump.

- Medium: Pulp and pulp containing air of consistency up to 6% / Similar liquids

- Material of Construction (Wetted parts) : Cast iron/Stainless steel/Wear resistant duplex stainless steel.

- Shaft seal: Stuffing box seal/Mechanical seal.

- Impeller: Open impeller with 3 or 6 blades

- Application: Pulp and paper industry, Environment protection industry.

KZ Series Wide-Channel Pulp Pump

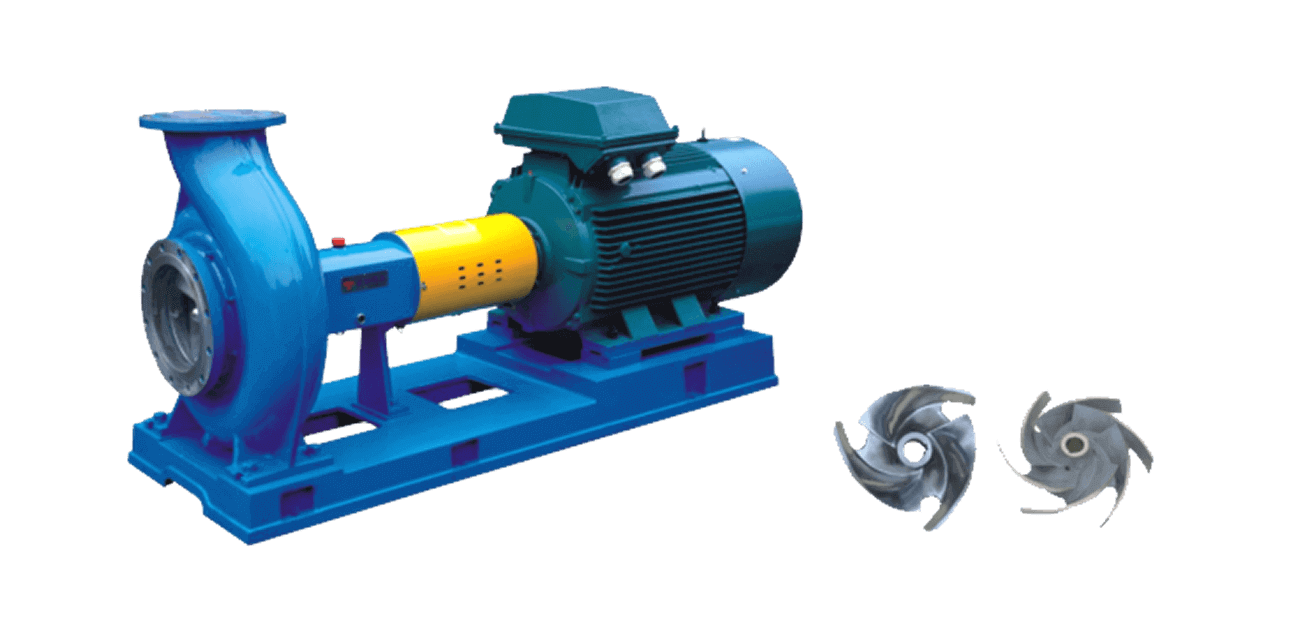

BKZ Series Semi-Open Pulp Pump

BKZ Series Semi-Open Pulp Pump

- Design: Single stage and single suction centrifugal pump.

- Medium: Pulp and pulp containing heavy abrasive or erosive contaminants up to 5% consistency.

- Material of Construction (Wetted parts) : Cast iron/Stainless steel/Wear resistant duplex stainless steel.

- Shaft seal: Stuffing box seal/Mechanical seal.

- Impeller: Semi open impeller with 3 or multi blades.

- Application: Pulp and paper industry.

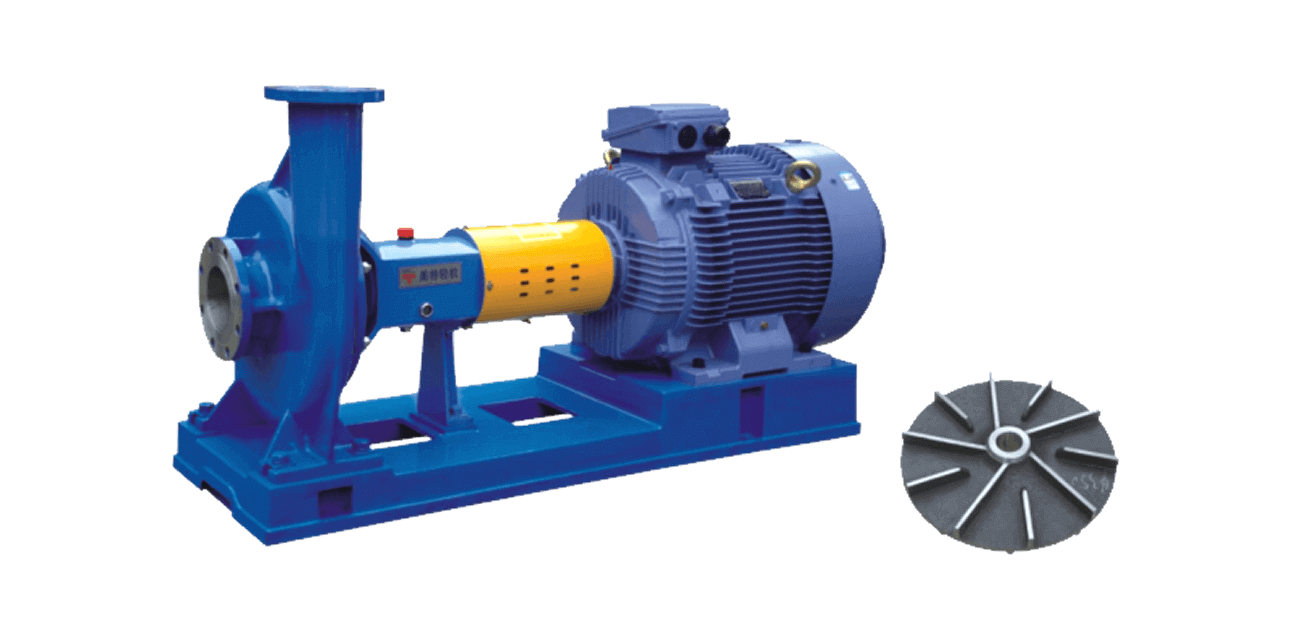

WP Series Vortex Non-Clogging Pulp Pump

- Design: Cantilever structure and vortex impeller, large width of vaneless cavity.

- Medium: Large solid particles such as wood chips, plastic blocks and long fiber materials like rag, straw rope, nylon rope, plasic film, etc… having high air content, high viscosity and easily damaged medium.

- Material of Construction (Wetted parts) : Cast iron/Stainless steel.

- Shaft seal: Stuffing box seal/Mechanical seal.

- Impeller: Vortex impeller.

- Application: Pulp and paper industry.

WP Series Vortex Non-Clogging Pulp Pump

KH Series Chemical Process Pump

KH Series Chemical Process Pump

- Design: Single stage and single suction centrifugal pump.

- Medium: Abrasive, Viscous, solid-containing and air containing fluids in high or low temperature.

- Material of Construction (Wetted parts) : Stainless steel.

- Shaft seal: Stuffing box seal/Mechanical seal.

- Impeller: Open impeller with 3 or 6 blades.

- Application: Pulp and paper industry (alkali recovery), Environment protection industry, Pharmaceuticals industry, Food industry.

MHB Series Chemical Process Pump

- Design: Single stage and single suction centrifugal pump.

- Medium: Clean water or liquids without solids and fibers.

- Material of Construction (Wetted parts) : Stainless steel.

- Shaft seal: Mechanical seal.

- Impeller: Open impeller with 3 or 6 blades.

- Application: Pulp and paper industry(eg. Alkali recovery), Environment protection industry, Pharmaceutical industry, food industry.

MHB Series Chemical Process Pump

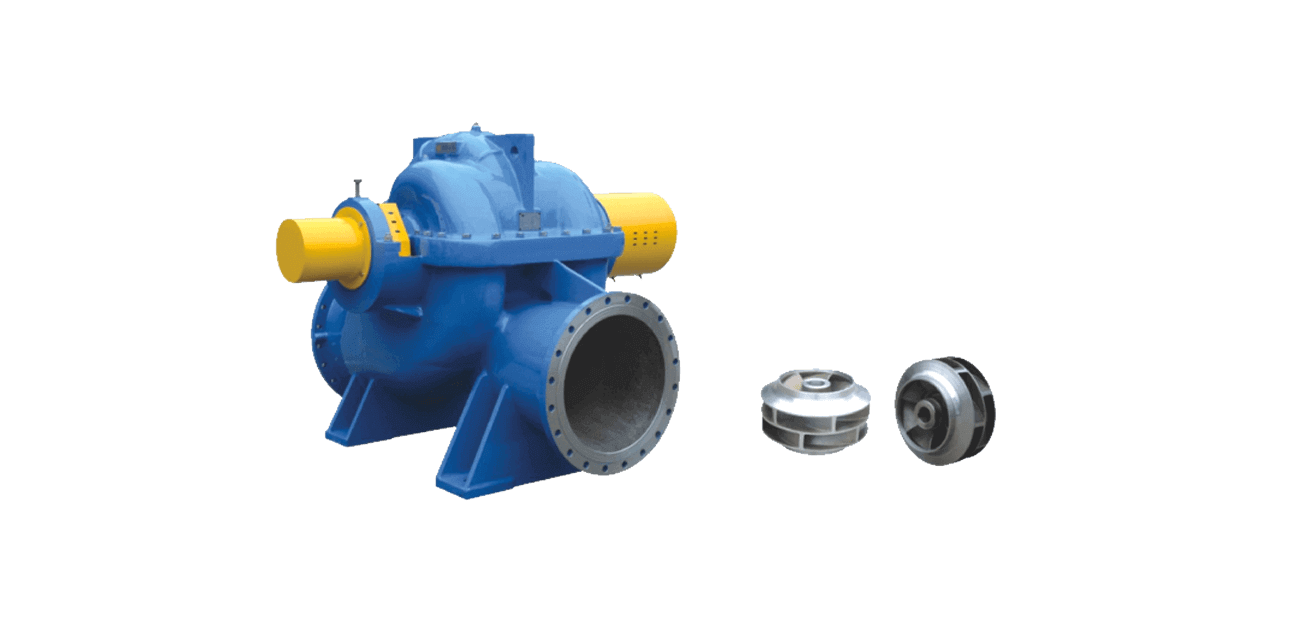

FJ Series Low Pulse fan pump

FJ Series Low Pulse fan pump

- Design: Single stage and double suction horizontal split-casing centrifugal pump.

- Medium: White water, pulp with consistency less than 1%

- Material of Construction (Wetted parts) : Cast iron/Stainless steel.

- Shaft seal: Stuffing box seal/Mechanical seal.

- Impeller: Double flow staggered impeller.

- Application: Headbox pump for paper, tissue and board production line and in pulp dewatering screen/cleaner pumps, backwater(white water) pumps.

KMC Series Medium Consistency Pumping System

- Consistency range: 8 to 18%

- Also performs simultaneous task of mixing bleaching chemicals with the pulp.

- Pump can be equipped with

- External independent degassing system

- Built-in degassing system

- Main advantages of 3rd generation KMC pumps are

- Increased output

- Increased head

- Increased consistency

- Reduced energy consumption.

- New KMC pump had better performance, stronger reliability and can replace any existing pumps.

- The new KMC technology can be used for medium consistency pumping without installing degassing pumps.

- KMC can also be used to pump non-wood fibers, such as bagasse, grass, bamboo and cotton, which are traditionally used as raw materials for pulping.

KMC Series Medium Consistency Pumping System

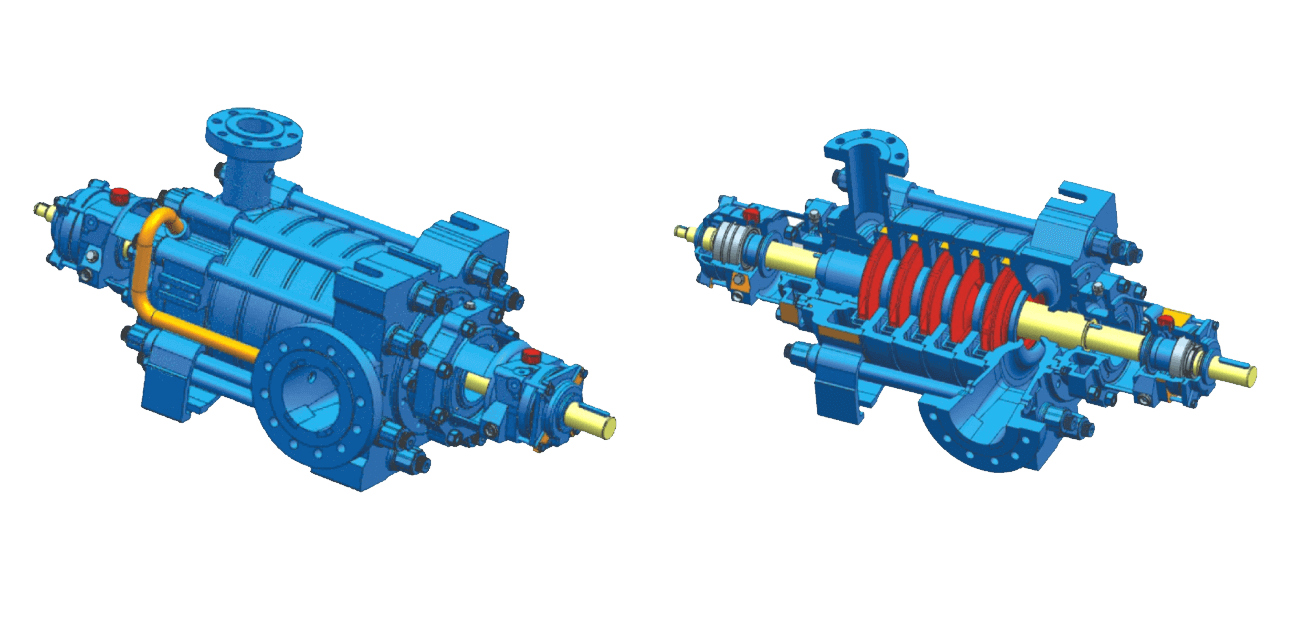

DMC Series High Pressure Segmental Multi-Stage Centrifugal Pump

DMC Series High Pressure Segmental Multi-Stage Centrifugal Pump

DMC high pressure segmental multi-stage centrifugal pump is one of the featured product series, which can install mechanical seal in line with API682 standard, widely used in power plant, paper mill, waste power generation, sea water desalination project, chemical industry and other industrial conditions. This product has the advantage of excellent hydraulic performance(high efficiency, low NPSHr), stable operation, convenient installation and maintenance, etc… DMC has high level of performance.